The following post is brought to you by ECONYL. Our partners are hand-picked by the Design Milk team because they represent the best in design.

What are you doing in 2021 to design or manufacture with sustainability in mind? What materials are you using in your designs or fabrications? These questions are ones that every designer or brand should be asking at the inception of every new project.

We’d like to introduce a smart option to you: ECONYL®. This versatile, sustainable nylon yarn can be recycled and regenerated infinitely, making it a smarter solution than virgin nylon that depletes natural resources. ECONYL is made from 100% waste that’s been pulled from landfills and oceans and performs the same as new nylon. Pre-consumer textile scraps and industrial plastic, as well as post-consumer waste, including used carpets and fishing nets, are what ultimately make up the material. What does this mean for us? That we can create and buy new products without ever tapping into new resources by using a material that can be endlessly recycled, reused and recreated. It exists and it’s ready to be used in your next project.

ECONYL’s parent brand, The Aquafil Group, is a leading manufacturer of synthetic fibers in the textile industry. Over the past decade they’ve invested in the research and development of sustainable materials, leading to the creation of ECONYL in 2011. Currently in use by more than 1,000 brands, you can rest assured that it’s been thoroughly tested and deemed a durable success. Because it’s created through chemical recycling, it’s possible to purify the collected waste and go back to the chemical building blocks of nylon. Possibly the biggest benefit of using ECONYL, rather than virgin nylon, is the 90% reduction in global warming it provides when directly compared, creating a positive environmental impact.

For every 10,000 tons of ECONYL raw material, 70,000 barrels of crude oil are saved and 65,100 tons of CO2 equivalent emissions are avoided. These are a few of the qualities that help ECONYL contribute to LEED credits in four different categories.

Behind the scenes it takes four steps to create the material—what’s referred to as the ECONYL Regeneration System. It starts with rescuing waste that’s then sorted and cleaned to recover all of the nylon possible. Through a regeneration and purification process, the nylon waste is recycled back to its original purity—making ECONYL exactly the same as virgin nylon. Afterwards, it’s turned into carpet yarn and textile yarn for the interior and fashion industries. The final step is on designers to create brand new products with nylon that has the potential to be reused again and again without losing its quality. In short, ECONYL’s production will increasingly be connected to the way the nylon products are designed and to their recyclability.

Sustainable textiles are a reality, and our desire to create and consume new products is seemingly endless. Today’s carpets might be next season’s trendiest clothing collection, eliminating waste and use of new resources. Designers are responsible for controlling the first phase of product development, and that can determine up to 90% of a product’s environmental impact.

The possibilities and fabrications really are endless for ECONYL in the fashion, carpet flooring, furniture, automotive industries and beyond. alcarol is an experimental design studio based in Italy who create innovative home furnishings that have been inspired by the environment and natural living. They also use avant-garde techniques. For example, their Ocean Networks Low Tables are multicolored as a result of various nets that have been tangled and melted together to create a transparent marbled effect. The glass slab legs and aluminum fixings can be easily removed to make each piece 100% recyclable when the time comes.

alcarol also used ECONYL to create their Fluctus Suspension Lamp; its illuminated surface meant to represent the ocean as seen from an underwater perspective. The light’s intensity can be changed and light animations can be created using an app on your smartphone, giving you the ability to create individualized light scenarios. In the detailed image of Fluctus, you can see the delicate details meant to portray the fragility of our oceans.

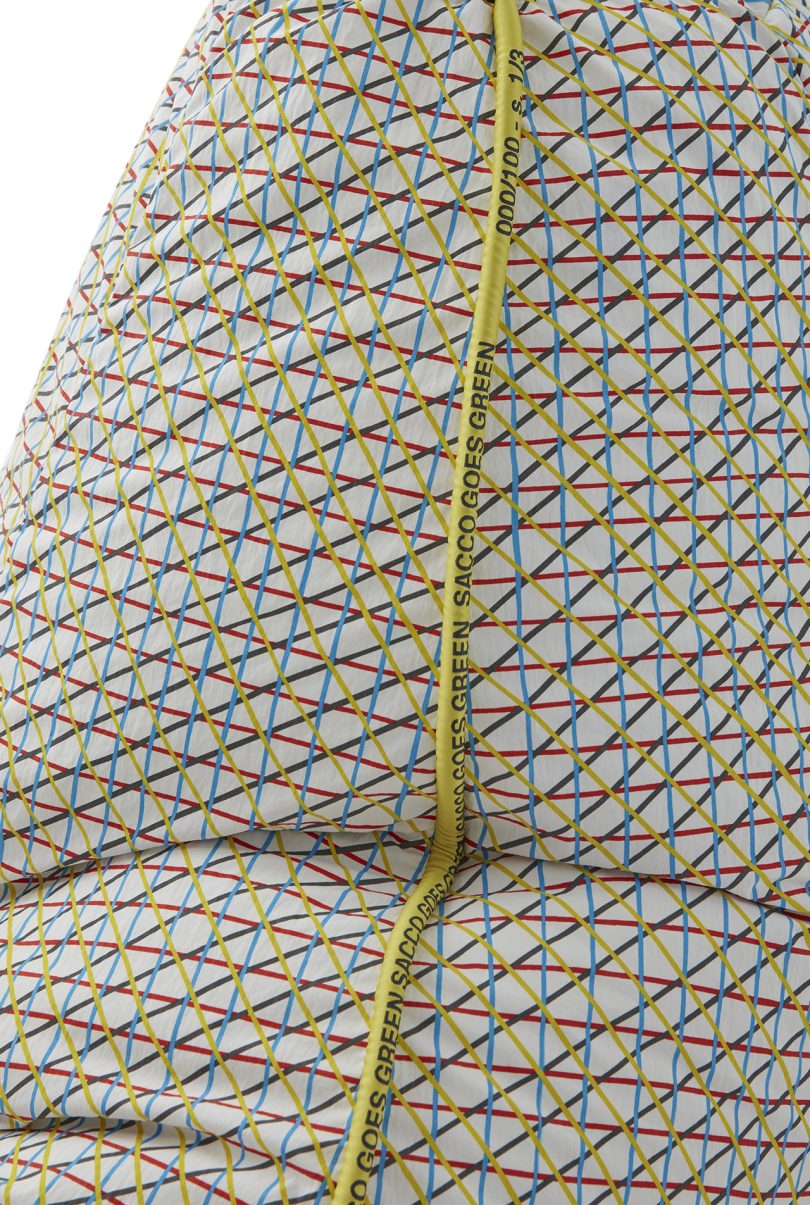

In celebration of the design’s 50th anniversary, Zanotta created a green edition of the popular Sacco seating in recognition of a need for global change. The numbered, limited-edition collection – SACCO GOES GREEN – replaced its internal padding with BioFoam microspheres, a biodegradable bio-plastic (PLA) derived from sugar cane. The outer cover is made of ECONYL that features three new patterns designed by Pierre Charpin, inspired by the netting used in the material.

Carpet flooring brand Interface has focused on premium products inspired by Earth’s natural habitats for years. Their latest, The Human Nature Collection, falls right into line with this ethos, and is made with 100% regenerated ECONYL fiber.

Furniture brand noho believes your space should be filled with pieces that look good while simultaneously doing good for the planet. Their noho move chair brings together comfort, versatility and earth-friendly design. Use it for everything from enjoying breakfast at the dining table to relaxing at the end of the day to powering through another workday from home. Each noho move chair is made almost entirely from waste plastic, including ECONYL’s nylon.

The proof of ECONYL’s high quality is clear, and the benefits evident. So, take a look at the projects on your to-do list and see where a 100% recycled, regenerated nylon material might make a difference in your industry and the future of the environment.

from WordPress https://connorrenwickblog.wordpress.com/2021/03/01/econyl-regenerated-nylon-is-making-the-world-a-better-place/

No comments:

Post a Comment