London-based HAYCHE released the WW Chair a few years ago and we thought it was time to revisit the modern Windsor design to see how it was made. Designed by Alejandro Villarreal, the chair features a solid wood seat resting atop four tapered legs, with a series of wire spindles that rise from the underside to join the wooden bar backrest. The WW Chair, where the first ‘W’ stands for Windsor and the second for Wire, originally came in just oak and walnut, but was later released in a variety of bold colorways. For this month’s Deconstruction, HAYCHE and Villarreal, take us inside to see how the design came about.

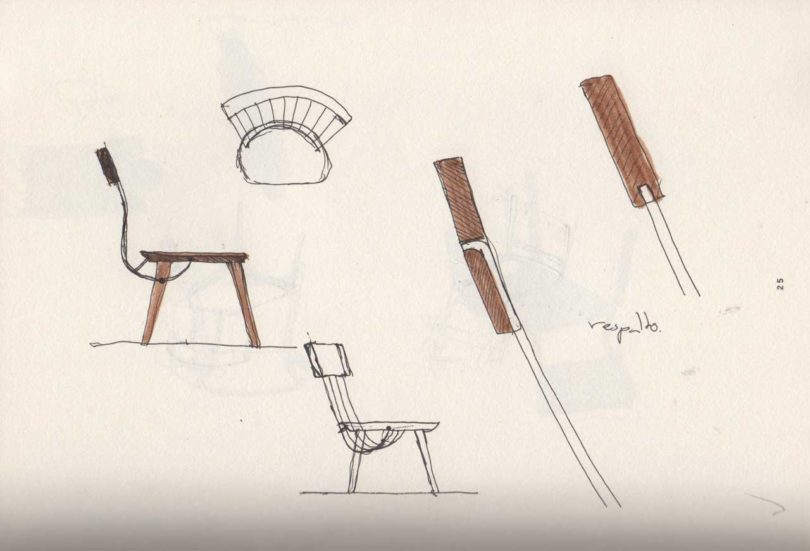

Villarreal’s working process starts manually: “My design process always starts with a hand-drawn sketch, which I find intimate and very personal,” he says.

“After that, I share the sketch with my design team and we start the painstaking process of 3D modeling.” The design for the WW Chair took six months and three prototypes to get right. “It was a very intuitive, iterative process,” says Villarreal.

The wooden parts of the chair are made from solid European oak or American walnut. The seat is partly CNC (computer numerically controlled) cut and partly hand carved, while the legs are milled using traditional machinery.

“Oak is my favourite wood and walnut brings a nice contrast and can be very beautiful as well,” says Villarreal. “It also happens that both materials are quite commercial.”

The distinctive back is made from 17 lengths of 5mm powder-coated metal wire welded to a solid plate that is attached to the underside of the seat.

They are bent into shape and held in place by a second metal plate embedded in the solid wood backrest. A low-level horizontal wire keeps them evenly spaced. “Wire was the natural material to choose for the back,” explains the designer. “It enabled us to achieve the desired thickness and structural strength.”

The use of wire also creates flexibility in a back that gently moves in response to the sitter’s weight, making the chair more dynamic and ergonomic than its predecessor.

Our production manager checks for quality control, and

our logo is carved into every single furniture piece we produce. before assembly.

On the contrast of wood and wire, Villarreal says: “I always want to respect the beauty of materials and I like bringing them together in a way that makes each one bigger or better than it was on its own.”

The WW Chair is available in solid oak, walnut, and both fabric & leather upholstery.

The WW Collection includes the WW Colour Series in collaboration

with Studio Makgill, and the newly launched WW Armchair, which is also available in the colour series.

WW Armchair Colour Series launched this year and its design is based on the same principle as the WW Dining Chair.

The collection extends to the WW Bar and Counter Stool and the newest addition the WW Table.

from WordPress https://connorrenwickblog.wordpress.com/2019/06/11/the-design-process-behind-hayches-ww-chair/

No comments:

Post a Comment